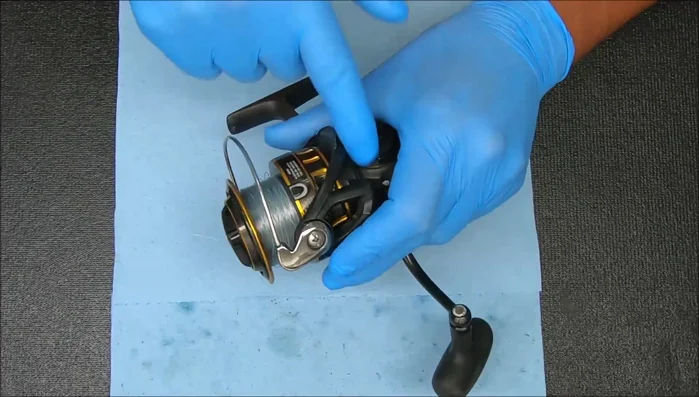

The Daiwa BG 4000 is a popular and robust fishing reel, known for its reliability and performance. However, even the toughest reels can encounter problems, and a common issue is a stuck spool, rendering the reel unusable. This frustrating malfunction can stem from various causes, ranging from simple line tangles to more complex internal mechanical issues. Understanding the potential sources of the problem is the first step towards getting your BG 4000 back in action.

This article provides a comprehensive guide to troubleshooting and repairing a stuck Daiwa BG 4000 reel, offering a step-by-step process to diagnose and fix the problem. Whether you're a seasoned angler or a novice, this guide will equip you with the knowledge and techniques necessary to resolve this common issue and return your reel to its peak fishing capability. Let's dive into the detailed repair process to get your reel spinning smoothly again.

Preparation and Safety Guidelines

- Screwdrivers

- Nut

- Always disconnect the reel from the rod before attempting any repair. This prevents accidental injury and damage to the rod.

- Use the correct tools for the job. Improper tools can easily strip screws or damage delicate components. Refer to a parts diagram if needed.

- If unsure about any step of the repair process, seek professional help. Incorrect repairs can lead to further damage and safety hazards.

Step-by-Step Instructions

Initial Access

- Remove the spool to access the rotor.

- Remove the handle.

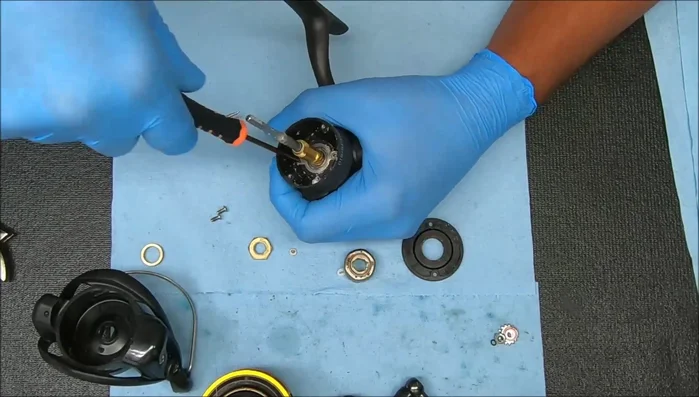

- Remove the cap to inspect the internal components (bearings, anti-reverse clutch).

Initial Access Further Disassembly

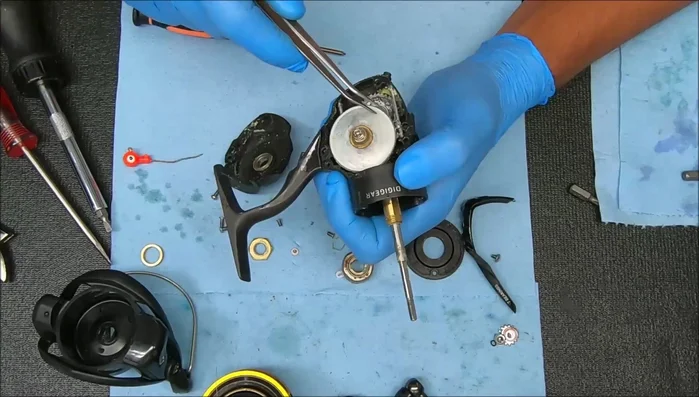

- Remove the two screws securing the cover to access the internal mechanism.

- Carefully open the reel to avoid damaging gears.

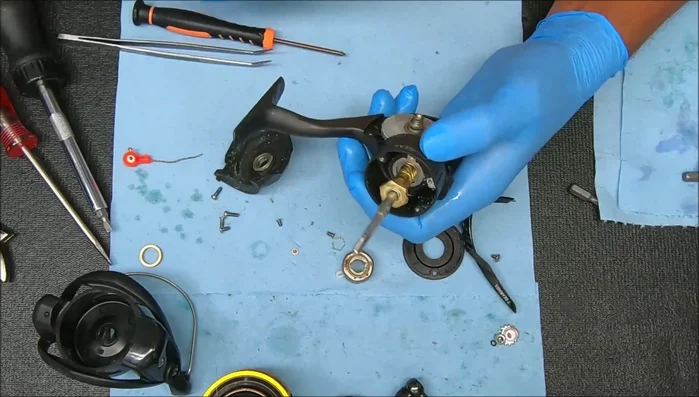

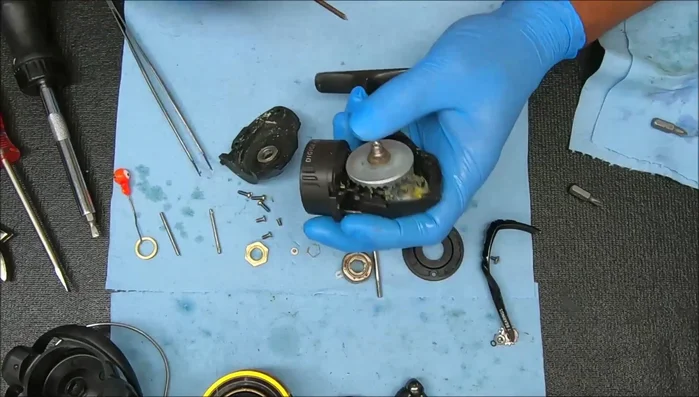

Further Disassembly Addressing Gear Assembly Issues

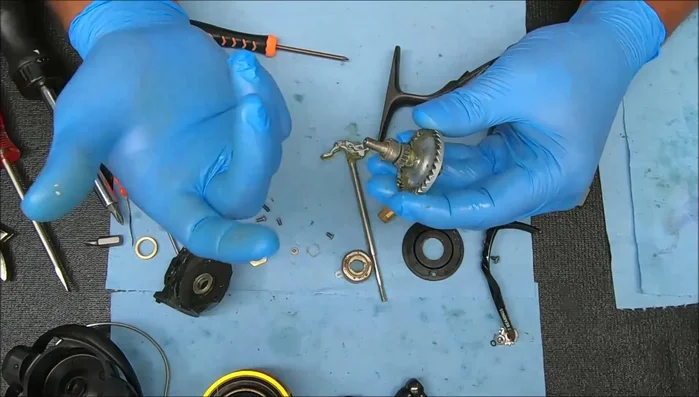

- Inspect the supports for any damage or fusion to the gears.

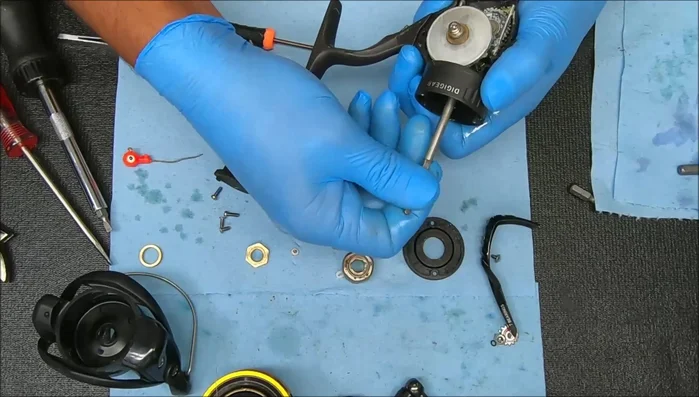

- Use a nut on the pinion to help remove the gear assembly.

Addressing Gear Assembly Issues Bearing Inspection and Repair

- Check the bearings for functionality and smoothness.

- Check all bearings for movement and smoothness. Replace any that are damaged or seized.

Bearing Inspection and Repair Fused Component Separation

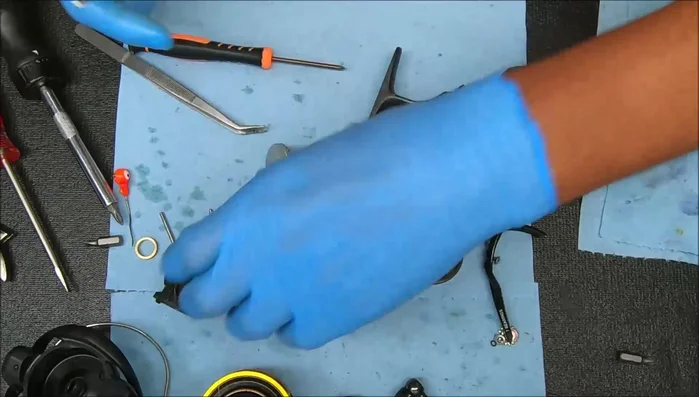

- Address the fused block and post issue, carefully separating them.

Fused Component Separation Transfer Gear Check and Removal

- Check the transfer gear for any obstructions and attempt removal if necessary.

Transfer Gear Check and Removal Clutch and Main Gear Repair

- Inspect and address the frozen or locked main gear and clutch.

Clutch and Main Gear Repair

Read more: Ultimate Fishing Reel Cleaning & Maintenance Guide: Prevent Corrosion & Extend Reel Life

Tips

- Be careful when disassembling the reel to avoid damaging delicate components.

- The design of this reel may allow excessive water entry which can lead to rust and component failure.

- Regular maintenance and cleaning can prevent rust and component lock-up.