This article presents a comparative analysis of abrasion resistance between Seaguar Blue Label Fluorocarbon and Ande Monofilament fishing lines. Both lines, tested at 20-pound test, were subjected to a rigorous abrasion test using a controlled pulley system and a coarse sharpening stone submerged in water. This method simulated real-world fishing conditions, allowing for a direct comparison of their durability under consistent friction. The experiment also included testing of braided lines (Power Pro and Suffix) to provide a broader context for abrasion resistance across different line types.The results revealed significant differences in both the failure mechanisms and overall abrasion resistance between the fluorocarbon and monofilament lines. While Seaguar Fluorocarbon exhibited higher tensile strength, failing suddenly under high friction, Ande Monofilament demonstrated superior abrasion resistance due to its gradual material loss. The study highlights the importance of considering line type and specific fishing conditions when choosing appropriate fishing line, emphasizing the trade-offs between strength, abrasion resistance, and other desirable characteristics.

Pros And Cons

- More dense than monofilament

- Thinner diameter

- More abrasive resistance (according to some)

- Refracts less light, more invisible underwater

- Broke with fewer pulls in the test

- Less abrasive strength than mono (based on the test results)

- Softer material

- Better abrasion strength than fluorocarbon (based on the test results)

- Lasts longer despite material loss

- Not as dense as fluorocarbon

- Floats and absorbs water over time

- Degrades over time from UV exposure

- Loses particles during abrasion

Read more: Best 5 Nylon Fishing Lines for [Year]

Test Setup and Methodology

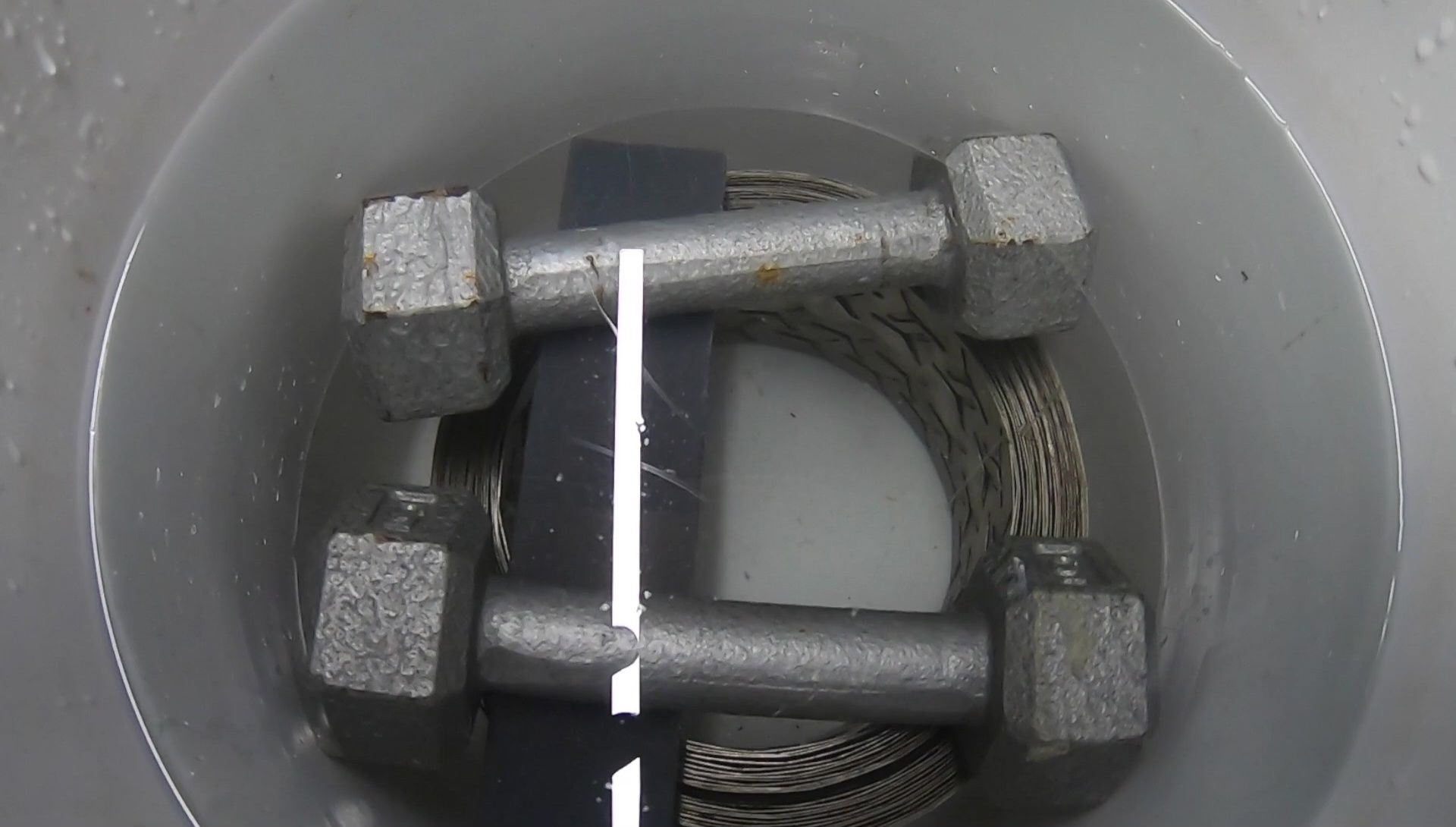

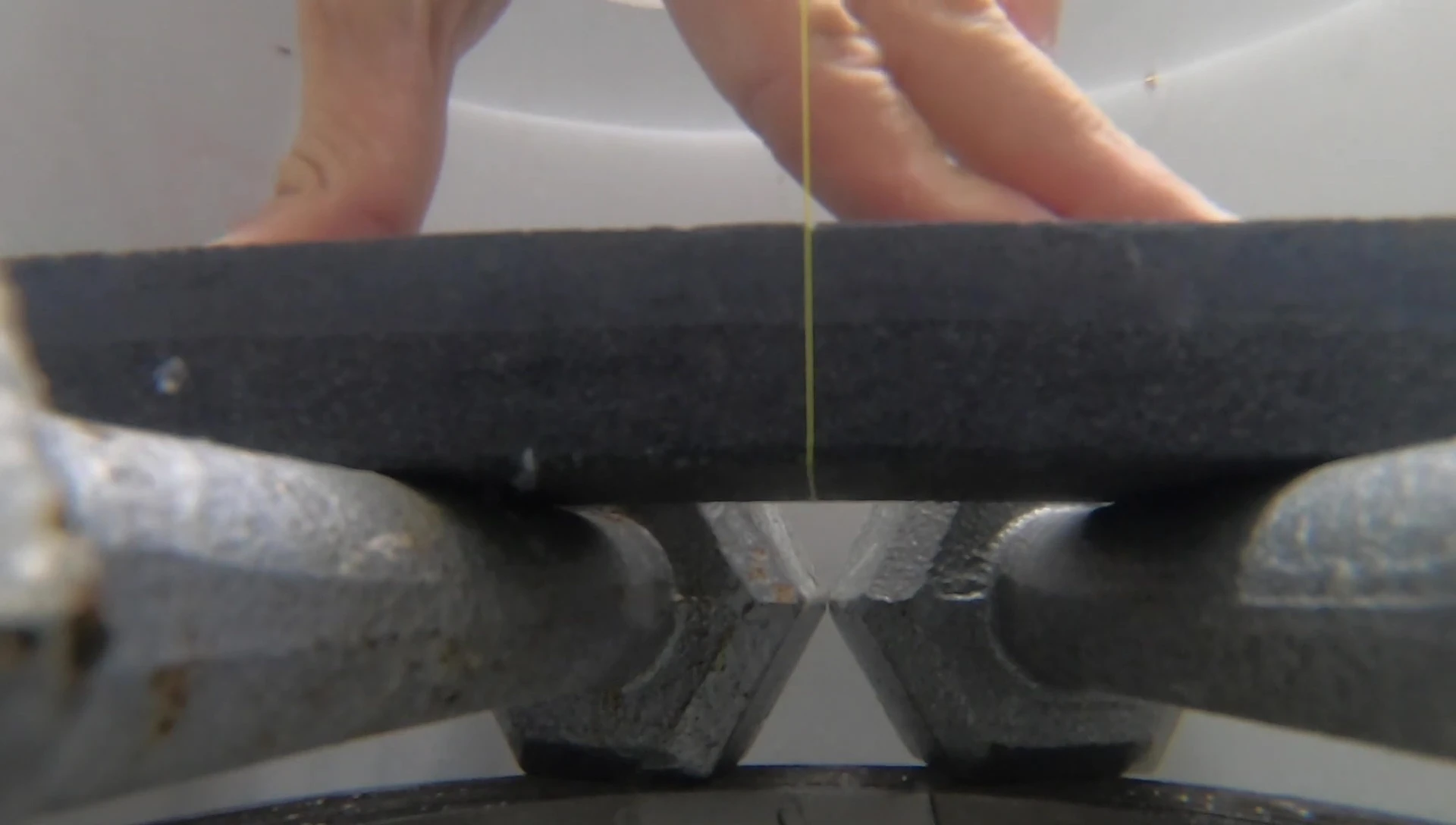

The experiment involved testing 20-pound test Seaguar Blue Label Fluorocarbon and 20-pound Ande Monofilament lines for abrasion resistance. A simple pulley system was used, with the line passing under a coarse sharpening stone submerged in room-temperature fresh water.

Approximately 12 inches of line was marked, and the line was repeatedly pulled up and down that distance against the stone. The number of cycles until failure was recorded for each line.

This controlled environment allowed for a consistent comparison of abrasion performance between the two types of fishing lines. Water immersion simulates real-world fishing conditions and ensures consistent testing.

Fluorocarbon (Seaguar) Performance

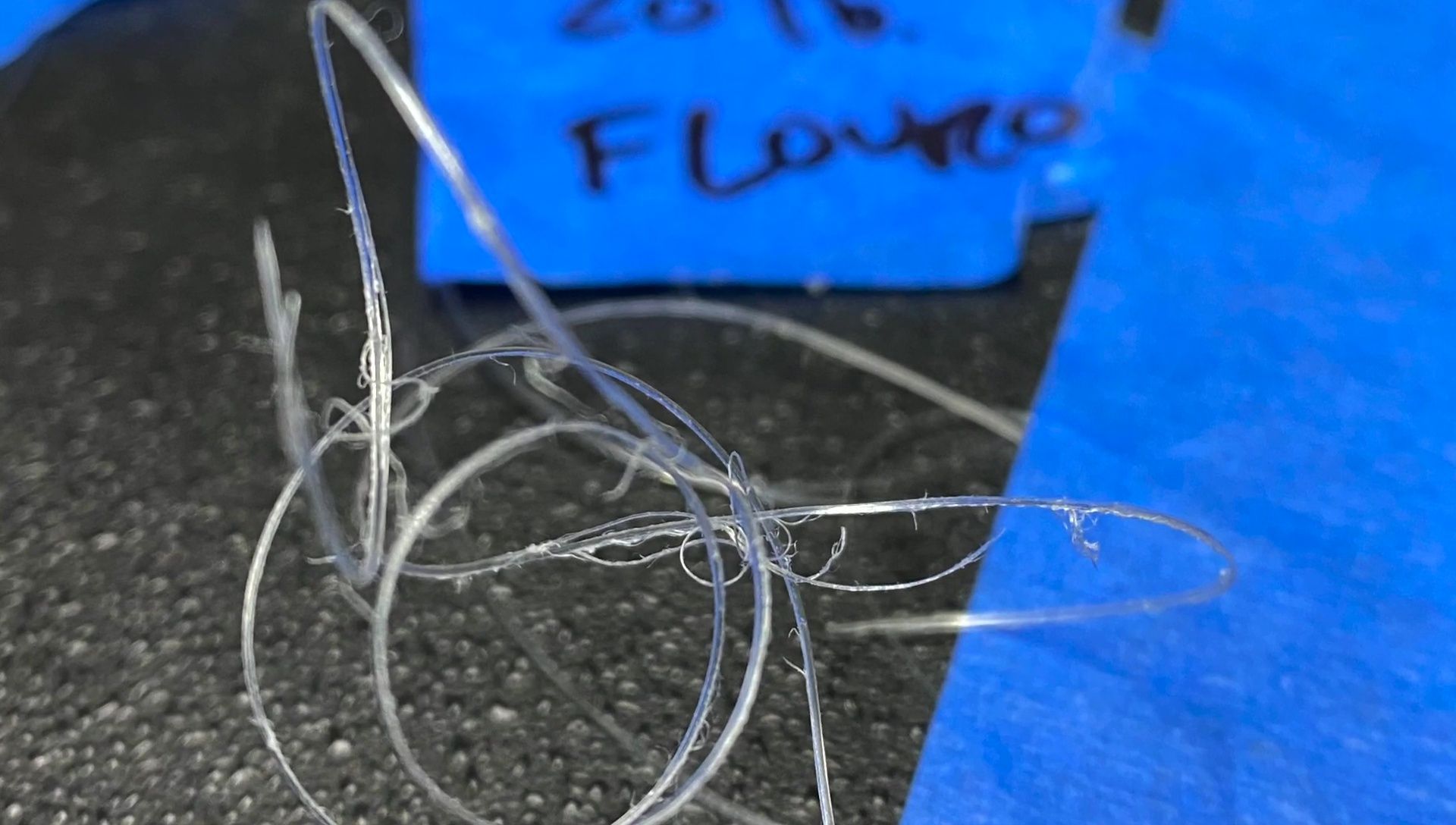

Seaguar Fluorocarbon, known for its density and thinner diameter, exhibited a different failure mode compared to monofilament. Instead of gradual abrasion, it tended to fail suddenly when the line experienced significant friction against the stone.

Underwater observations revealed that the fluorocarbon line broke cleanly, creating long string-like pieces. This suggests a higher degree of tensile strength but potentially less overall abrasion resistance in the context of this test.

The less abrasive nature of its failure suggests potential advantages in certain fishing scenarios, but in this specific, high-abrasion test, its early failure indicated a vulnerability.

Monofilament (Ande) Performance

Ande Monofilament, being softer and less dense, showed a different pattern of abrasion. The line gradually lost material, with small particles constantly being shaved off during the test.

While seemingly weaker given the continuous material loss, the monofilament demonstrated remarkable endurance, withstanding significantly more cycles before ultimately failing.

The gradual abrasion of the monofilament suggests superior abrasion resistance in prolonged, less intense friction scenarios. The softer material likely helps to better absorb and distribute stress from the abrasion.

Braided Line Control Test

For comparison, a 15-pound Power Pro Super Slick 8 and a 30-pound Suffix 832 braided line were also tested. Both braided lines failed after a single cycle of pulling the line across the stone.

This outcome provides valuable context and underscores the significant difference in abrasion resistance between braided and monofilament/fluorocarbon lines.

This demonstrates the unique strength and weakness of braided lines - high strength but low abrasion resistance under the conditions of the test.

Results and Conclusion

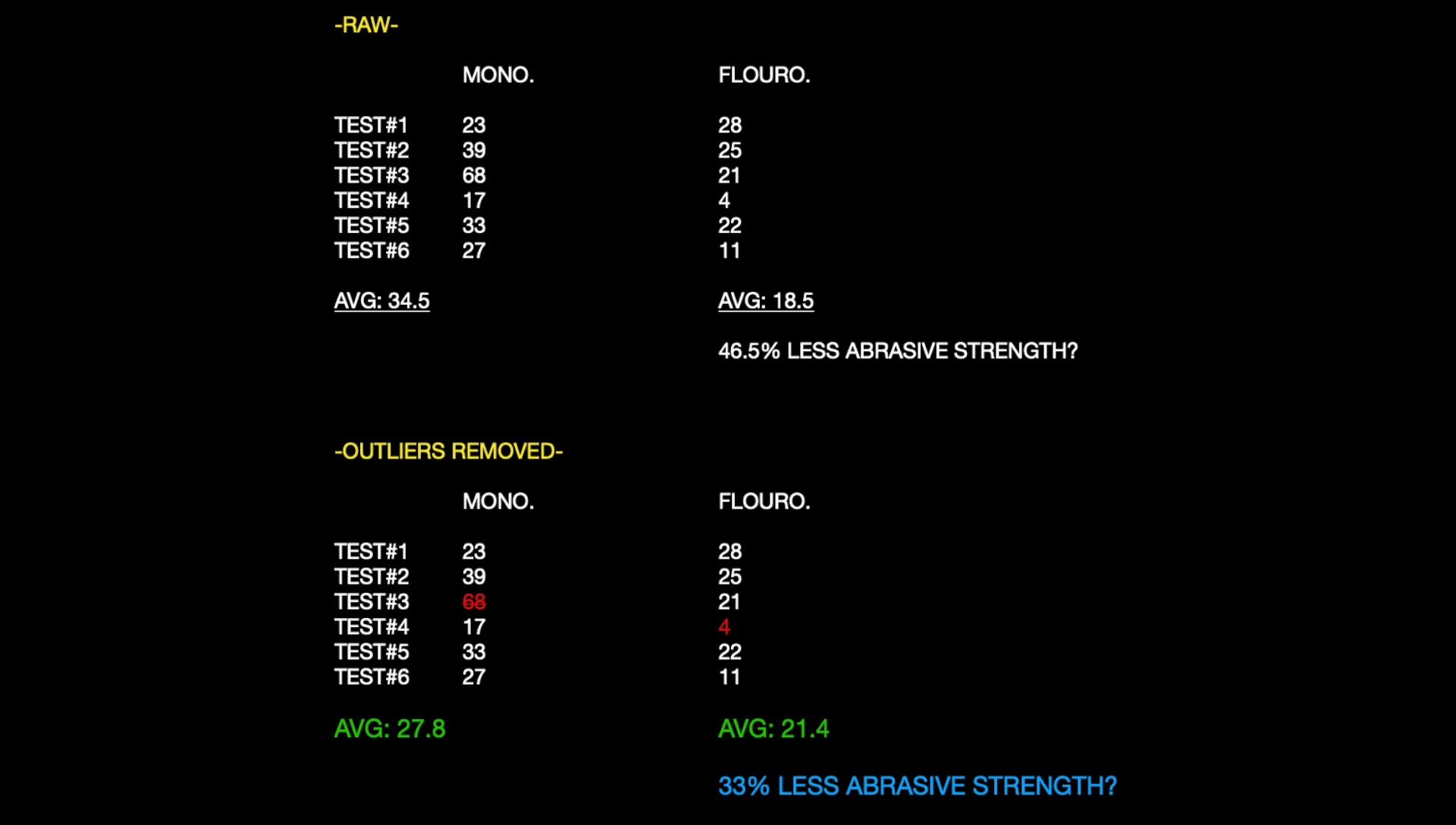

The average number of cycles until failure for the Ande Monofilament was significantly higher (approximately 34.5 cycles) compared to the Seaguar Fluorocarbon (approximately 18.5 cycles).

Even after removing outliers, the monofilament still outperformed the fluorocarbon in terms of abrasion resistance. The difference in failure mechanisms and material loss highlight the distinct properties of each line.

While fluorocarbon offers advantages in invisibility and other qualities, this test clearly demonstrates Ande Monofilament's superior abrasion resistance, particularly in rough, rocky fishing environments. Considering cost, the monofilament appears more suitable for this application.